In construction, the best ways to reduce expenses typically involve cutting either material costs or the time required for the building process. But what if you could do both?

Today, the Lacy Construction team is excited about a brand new process that we’ll soon be offering to our clients. Called “Hi-Tech Tilt™,” the technology involves the integration of structural metal studs with wire mesh embedded in the standard concrete slab. The slab can be utilized for both floors and walls with load-bearing capabilities.

How does it work?

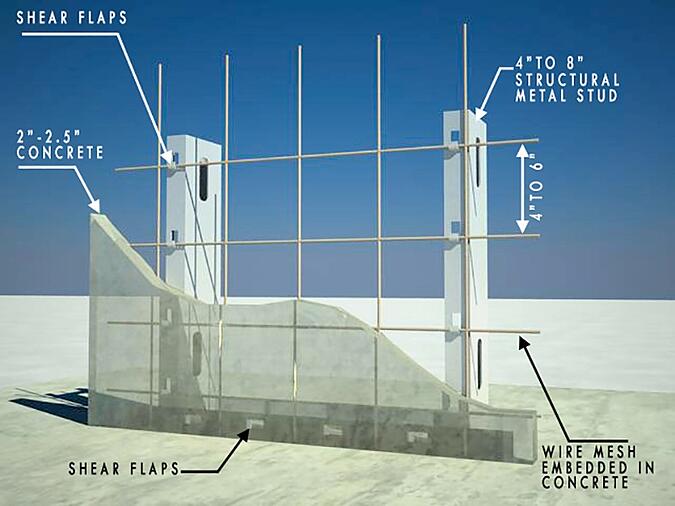

Let’s dig into a few details. A patented composite building technology, Hi-Tech Tilt™ features panels framed with metal studs and track. The walls can be prefabricated in a plant or cast on-site on the building foundation. The concrete skin is two inches thick, while studs and track are normally two inches by six inches and comprised of 16-gauge steel. The steel is attached to the concrete via tabs punched out of the side flange of the studs and track. Tabs are punched four inches to six inches on center (OC) as recommended by structural engineers. The tabs are embedded into the concrete by using the building slab as a casting bed, similar to tilt-up casting methods. Instead of rebar, the panels are reinforced with wire mats.

Let’s dig into a few details. A patented composite building technology, Hi-Tech Tilt™ features panels framed with metal studs and track. The walls can be prefabricated in a plant or cast on-site on the building foundation. The concrete skin is two inches thick, while studs and track are normally two inches by six inches and comprised of 16-gauge steel. The steel is attached to the concrete via tabs punched out of the side flange of the studs and track. Tabs are punched four inches to six inches on center (OC) as recommended by structural engineers. The tabs are embedded into the concrete by using the building slab as a casting bed, similar to tilt-up casting methods. Instead of rebar, the panels are reinforced with wire mats.

The resulting product is a structurally sound building panel with both a finished outside surface and a studded inside face ready for finish-out. The inside frame allows all utilities (electrical, plumbing, and HVAC) and insulation to be installed before the drywall is screwed on to the studs. Best of all, the outside can be cast with feature strips or decorative reveals, and there are several methods available for the thermal breaks often specified by architects.

The construction panels are stronger but lighter than solid concrete or concrete block. The result? The bonding and adherence of the concrete to steel results in a very strong composition of known and tested conventional materials. Now we have a competitive edge over tilt-up and other building systems — allowing us to build stronger buildings not only faster but also at a lower cost.

How does Hi-Tech Tilt™ lead to generous savings in both time and money compared to traditional tilt-up panels?

Consider that this new method:

- uses 66 to 75 percent less concrete

- allows erection times up to 40 percent faster

- reduces finishing labor costs

- does not require spread footing or concrete pour strips

- accommodates erection of panels within 48 hours after pouring of concrete

- allows the use of a smaller crane and reduces the rental time required for specialty construction equipment

- affords easy installation of insulation

- allows the installation of utilities within the panels

Since 1946, Lacy Construction has been pursuing the best technologies for commercial construction. Today, our expertise in a host of specialties—from various design-build options to feasibility studies, decorative concrete, ICF construction, and metal buildings—have made us a natural choice for a long list of satisfied clients in Nebraska, across the Midwest and beyond.

Two things we have learned in all these years? The first is that change is inevitable, as building technologies grow and improve. The second is that we love nothing more than helping our clients take advantage of the improvements in performance and the reduction of construction costs that have resulted when innovation and technology are employed.